Are you interested in products?

Contact us!

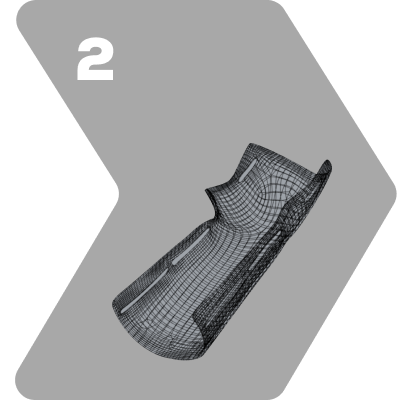

ENforce ultra light

Individually fitted orthosis for the hand and forearm

A 100% fitted orthosis is manufactured based on a 3D scan, in 3D printing technology. The durable and rigid support material guarantees safety and stabilization of the joint. The combination of a perfect fit with a significant weight reduction (on average only 90 g) means that the patient does not feel any additional load during use. The orthosis is delivered to the patient’s house within 48 hours.

Delivered within 48 hours

3D scanning station

It is ergonomic

It connects wirelessly

Scanning takes less than 30 seconds

Its overall dimensions are 550 x 830 x 470 mm

Innovative materials

Sleeve made of Q-Skin®

It can be washed

It does not cause abrasions

It has a certificate of compliance

with Directive 528/2012/EU

By wicking away moisture,

it prevents the production of odors

Due to the bacteriostatic agent, it maintains

the natural bacteria level on the skin

Innovative materials

Support made of polylactide (PLA)

One orthosis, numerous possibilities

Support made of polylactide (PLA)

Follow us on our social media: